Value Synergy Ltd offers a range of technical services in the oil & gas industry. To ensure excellent service delivery, some of the services provided are done in collaboration with partners and OEMs to bridge any identified gaps.

These technical services are not limited to:

- Hot Dip Galvanising Services

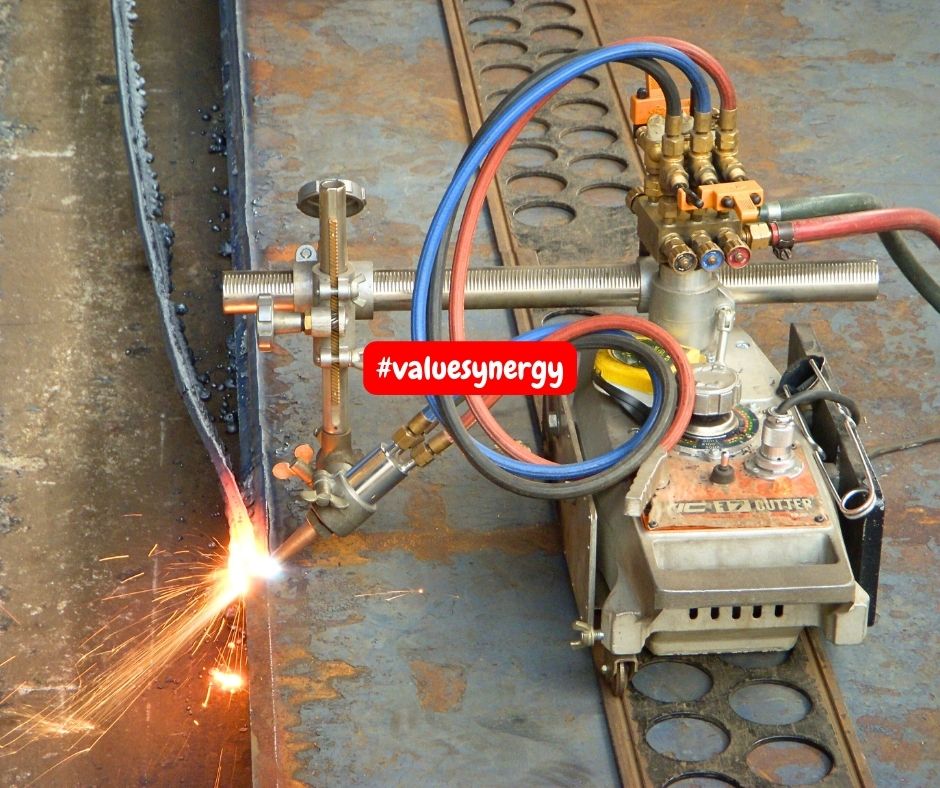

- Fabrication Works

- Non-Destructive Testing (NDT) Services

Hydro Testing: This is a non-destructive testing carried out on newly welded vessels especially newly fabricated pressure vessel or vessel that has just undergone leakage repair works. This is to ensure they are leakproof. It is done by filling the steel vessel with water at room temperature and applying pressure to specified bars depending on the steel vessel.

Value Synergy offers hydro testing services, on both contractual or call-off basis depending on clients’ specified needs.

Pigging & Flushing: Petroleum Pipelines under operation retain a thick slurry mix of oil, sand, and water which reduces the liquid flow rate through such pipelines and eventually if not cleaned, will lead to total blocking of the pipeline and shut down of the flow system. This cleaning is a routine exercise to maintain the efficiency of the flow system.

Pigging & flushing entails passing a pig, under high pressure, through the pipeline using a piece of equipment called the pig launcher. A pig is a big cylindrical synthetic brush used in pushing the hard slurry of oil and water out of the pipeline with high pressure.

Value Synergy offers safe pigging & flushing services either on a routine contract basis or on a call-off basis according to the client’s needs. We also dispose of the waste from the pipeline in line with global industry standards.

Calibration Services: Our calibration services are for tanks and fluid retaining vessels and we get a third-party certifying body to certify the calibration.

Non-Destructive Testing (NDT) service: We also conduct material testing using X-ray and radioactive agents to determine the integrity of welded joints and structural steelworks. This we do either onsite or offsite in a very timely fashion and generates accurate reports immediately.

Valve Repair & Maintenance: Value Synergy offers valve maintenance services for various grades and sizes of valves. We can pick up the valves from clients’ locations, retrofit, refurbish, and send them back to the location or site according to clients’ orders. We can serve you both on an annual contract basis and on a call-off basis.